The Duravant family of operating companies serve the food processing, packaging and material handling segments.

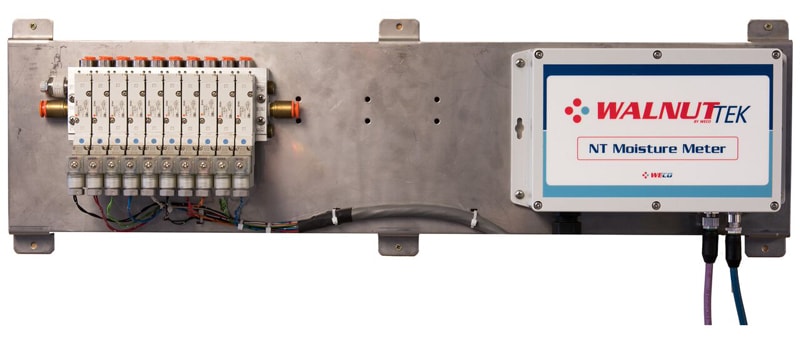

WECO provides a broad range of sorting and measurement products to the Walnut huller, in-shell, and processor markets.

Our WalnutTek sorters have long been the industry leader in speed, quality, and savings. Always working with our customers, WECO has also developed a Walnut Kernel Grader to automate the color grading process, Moisture Monitoring systems to automate drying, and AgTrack software to track product through the entire process. See what WECO can do for your operation.